The 1957 Triumph Freebird front fork and wheel are getting worked over in preparation for chrome plating. This top clamp had pitted chrome plating and was stripped and powder coated a few years back. Now that the bike is heading to the Bornfree Show 11, it is going to get chrome plated along with the other front end parts. This picture is after some contouring and buffing, with a little more to go.

The last three days work, stripping, grinding, buffing, making some new parts, and truing up others.

Working on tiny details like grinding off 1.5mm of the top of the fork lower so the threads don’t show down below. These parts were also powder coated and had to be stripped. The welds for the fender stays and some scratches and dings were worked over and polished out.

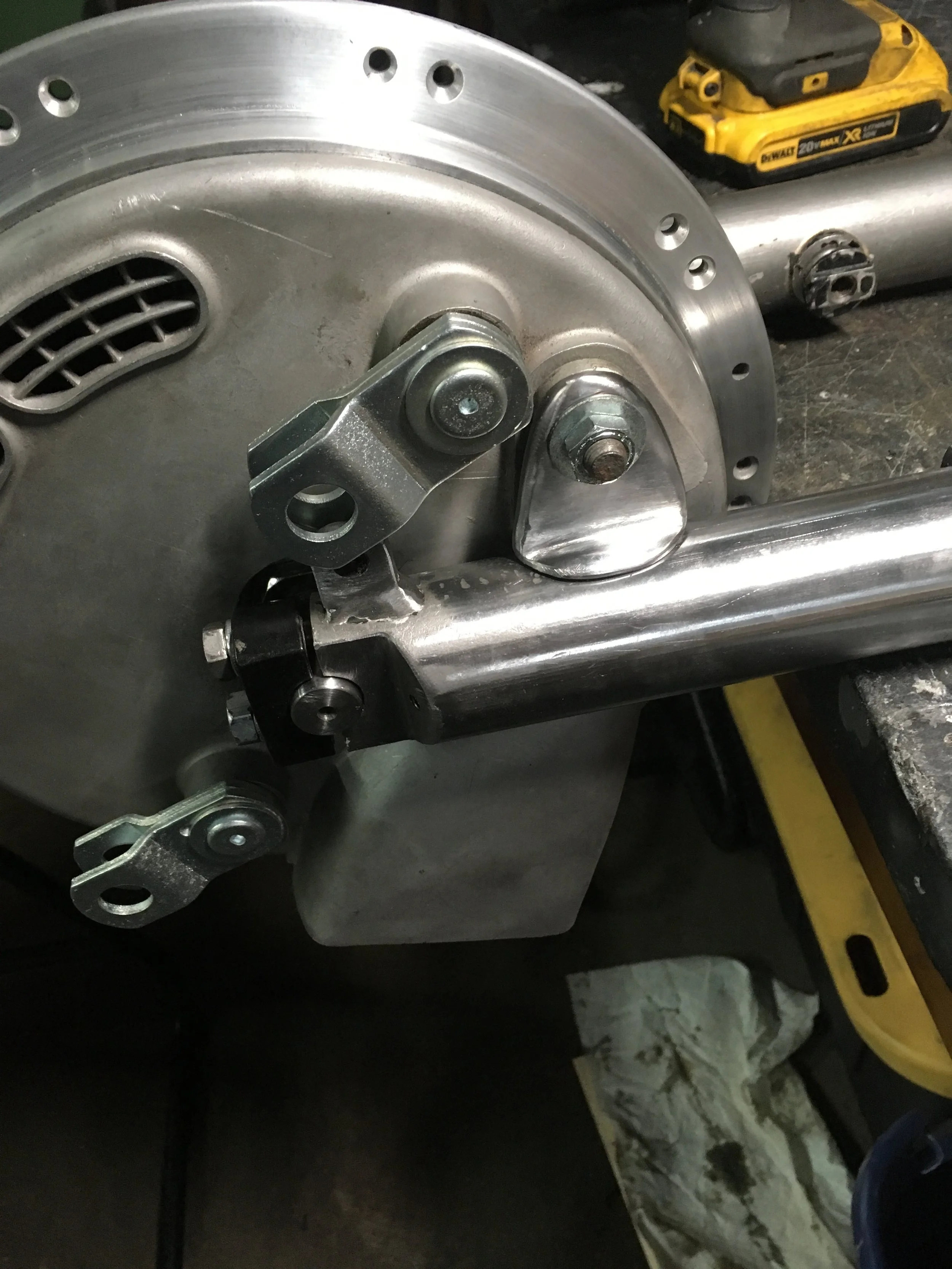

Finally made the decision to go with a conical hub on the front wheel. One of the limitations with the stopping power on these hubs is the length of the brake actuator arms. Adding another 3/4'“ in length doesn’t sound like a lot, but it is almost 50% longer than the original. A new arm was bent from 1/8” steel and welded on the original shafts.

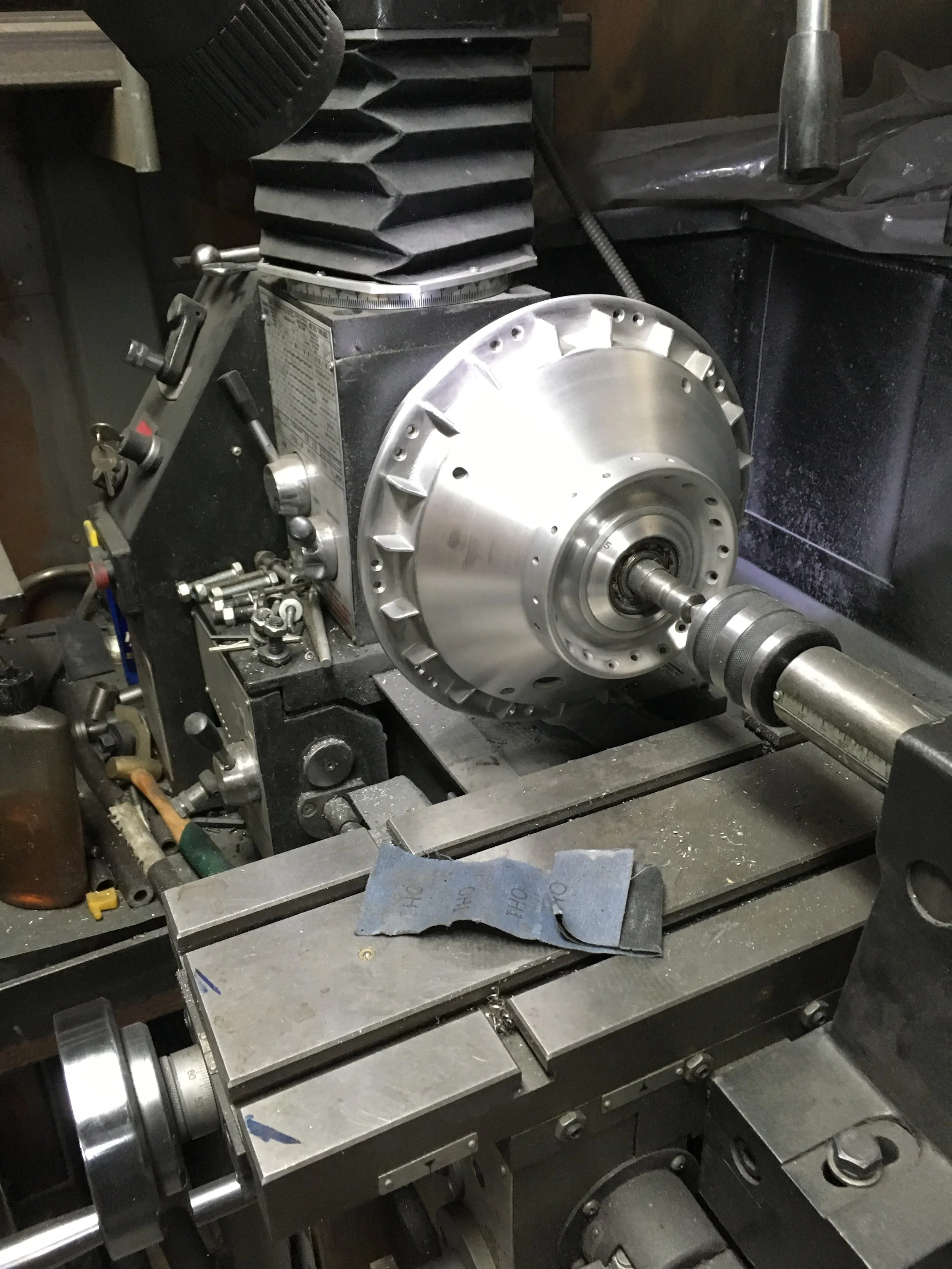

I was getting ready to weld and re-cut the 70’s conical hub axle ends to match the 1967 front fork, but realized the 1967 axle was a perfect fit and switched it out. There was a slight drag on the wheel in one spot, and the hub was studied for a while to try and figure where it was coming from. Some casting flashing on the rim appeared to be the cause and was cleaned off, but did nothing to solve the problem. Turns out it was the bearing locking ring hole being a little off and rubbing on the brake plate boss that passes through it. It had been rubbing this way for a while by the looks of it and probably made a pulsing high pitched squeal as it heated up. I got this at the Barber swap meet back in 2013 with the idea of using it for this bike, but went back and forth with some other hubs before returning to it. One of the things I like about it is the scoop and how it resembles the exhaust fishtails.

Another job done was the brake panel stay, which was brass brazed on the right fork tube. It was made from two 1/8’ steel plates that were welded on the edges and bent out at the bottom to make the base. Brass brazing was how the other fixtures were affixed on the fork lower by Triumph originally, and was the best choice to minimize distortion on the fork bore.

After making the brake stay bracket, it was mocked up and a line scribed around the base to mark where it was to be mounted.

The outer rim on the left side of the hub was close to the fork leg and was taken down a couple millimeters. Some sanding on the cone was done, and the inner brake lining was trued up.

Details, details. The mount for the sub-frame was finally completed. The ears ad to be trued up, washers made, and the everything buffed out. Still not certain the frame will be chromed or painted. After the contouring work was done on the muffler mounts and gussets, painting it might give the impression it is a Bondo bike.

Waiting for paint to cure up before this can go back on the 1993 Harley-Davidson FXR custom build.