The 1955 Norton “Norsaki” build, a featherbed frame with a Kawasaki 400 triplets been painted, and assembly will begin shortly. The 1967 Triumph Mountain Cub is assembled and awaiting the oil and gas tanks to return from paint. The seat cover is done on the Norton, and the Cub seat is in the process of being upholstered in the original color scheme.

The seat and strap were done in Napa leather. A stainless thumb screw was carved for the tank strap anchor. Black sheepskin is sewn underneath, where it contacts the tank.

A simple pattern was chosen for the seat cover. Can’t wait to see it on the seat pan. The cover was made by Xtreme Upholstery in Denton, Texas.

The original Kawasaki S3 tach fit perfectly in the Lucas headlight shell, but finding a working one that was also presentable proved difficult. In the search, three seperate units were sourced (one was returned as defective,) and a single unit with a restorable bezel and an intact output shaft was built. There is also a custom face being printed.

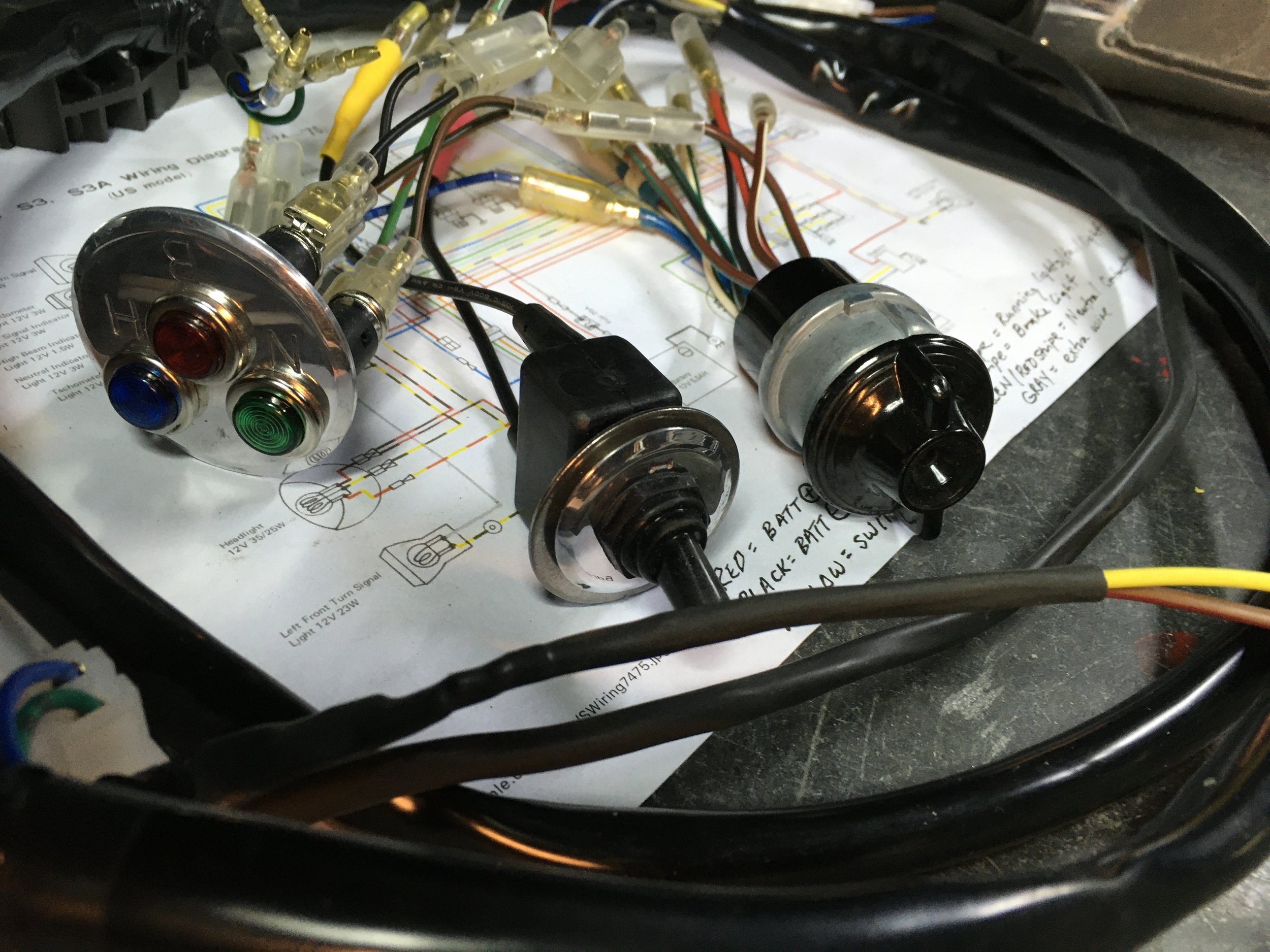

The ammeter hole in the Lucas headlight shell needed filling, so this panel with original Lucas jewel indicator lights was machined from aluminum.

A special washer was made to mount the light switch, and another aluminum bezel was made for the ignition switch.

With everything mocked up, the lines are becoming a little more clear. The bike started life as a 1955 Dominator. When designing the custom parts, I tried to keep some of the original feel. The owner of the bike wanted a classic cafe racer style, with a straight tank-seat line, straight bars, and bobbed fenders (the original fenders are quite large and a little heavy.) Even with the cafe styling, the new seat is only slightly shorter than the original, retaining the ability to take a passenger.

Some rear loops for the passenger pegs were made from 7/8” tube. Some old Harley Davidson pegs were the closest match to the rear-sets used in the front. Interestingly, they are made from some minibike handlebars, cut from the pullstart mini put together for Skratch’s Garage (seen in the December 31 post.)

The front fender mounts and lower stay were added to an un-drilled vintage fender. The front hub is said to be a Grimeca, with 4 leading shoe brake pads. It will have some stopping power.

The tail end is looking pretty tight. The large wheel T-nut seen on the left side, and the rest of the wheel hub are from a Vincent Black Lightning, a bike of which only thirty-some odd were made. The parts were found by Big D Cycles, in Dallas, who built up the wheels, shocks and handlebars. They decided to go with the hub to solve the brake/sprocket configuration, and because it was just so cool. There is also a brake panel stay that releases by a spring-loaded slide, making the rear wheel removable without tools.

The seat pan on the 1967 Triumph Mountain Cub was made up. The lower bracket is made from 1/8” flat bar, with an aluminum pan made from .090 sheet. Mobtown Mike Smith will be taking care of it.

I like this technique for concealing wires under the fender. A brass tube connected between the entrance and exit holes, with small plates on each end that utilize the existing fender mounting holes to keep it in place.

The tail light unit was made from an old cymbal, a busted minibike tail light lens, and a brass plumbing fixture. The design was inspired by the iconic Sparto “Limp dick” tail light mount that was on the original bike. With the bobbed fender, there was little room for the original, and it looked out of place. This one is scaled down, and crosses over the rear frame loop.

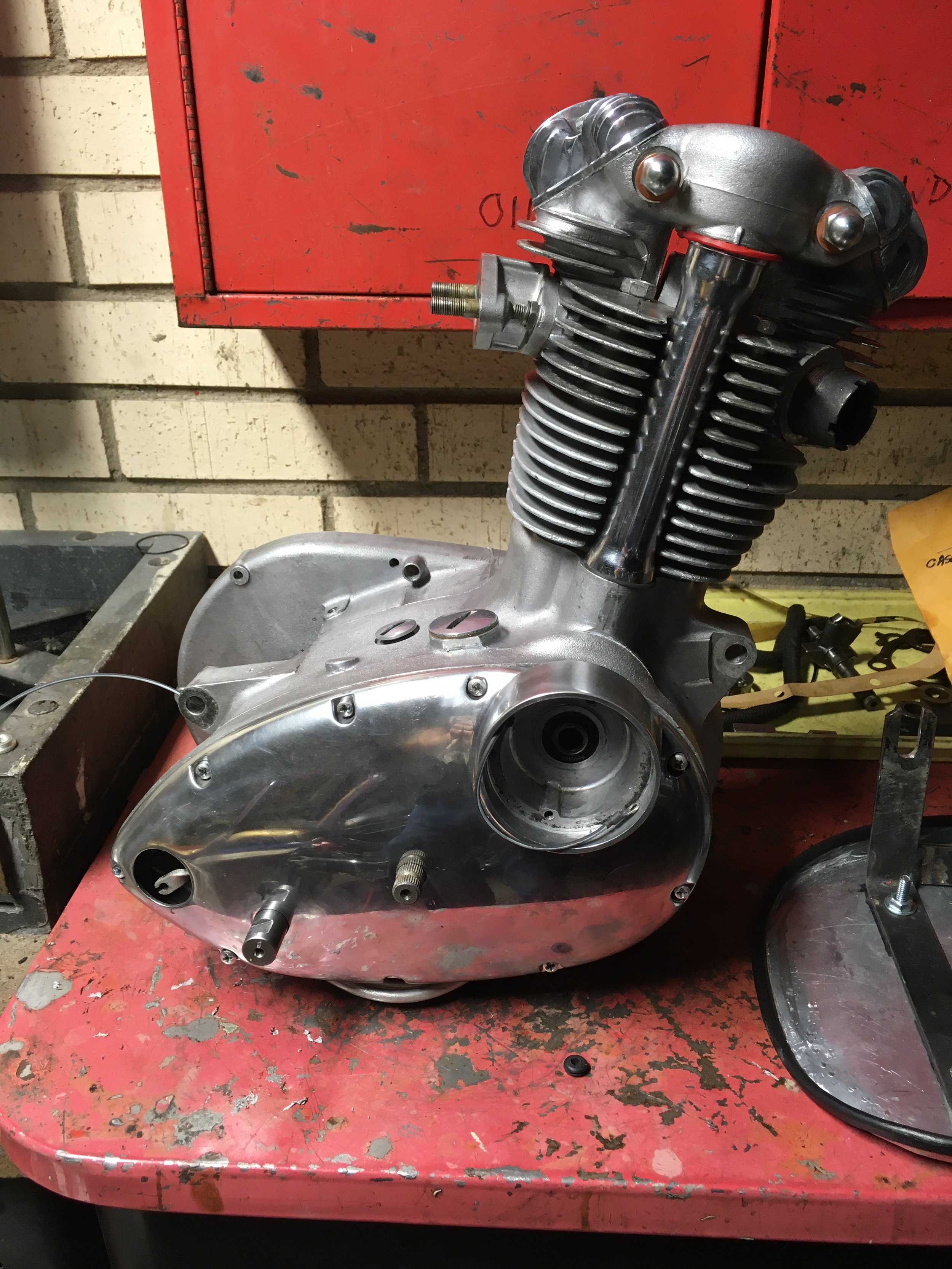

Such a beautiful engine, designed by Edward Turner. In this picture, the engine is awaiting the points assembly, prior to installation.

The timing degree wheel along with the spark plug gauge, feeler gauge, and a test light are all you need to time the engine. I think the JapaneseHonda system is a lot less complicated, and more precise.

Some of the grief of trying to rebuild a vintage foreign bike. This is a picture of the muffler sent to me after a nearly four month wait. Obviously the wrong one, it cannot be made to fit, and looks to be made for a dual low-pipe set up. Of course the vendor is unresponsive to emails. When it arrived, the muffler was in a plastic bag, with more than a little bit of rusty water inside the bag, covering the muffler. A sign of attention to detail and competence…not!